In today’s competitive and complex marketplace, ABC inventory analysis is a principle of operational optimization. The backbone of any successful business is an efficient and responsive supply chain. As a supply chain manager, purchasing manager or director, you are well aware of the symbiotic relationship between robust inventory management and overall supply chain performance. In fact, we invite you to read the article Demystifying Manufacturing Inventory, the first in our series on inventory management.

Introduction

Effective inventory management underpins the formidable architecture of logistics success. It is at the heart of the balance between cost and customer satisfaction. Poor stock management can result in shelves full of unsold items or, conversely, empty shelves leading to lost sales and unhappy customers. In this delicate balancing act, ABC stock analysis is an essential tool, paving the way to efficient, streamlined operations.

What is ABC inventory analysis?

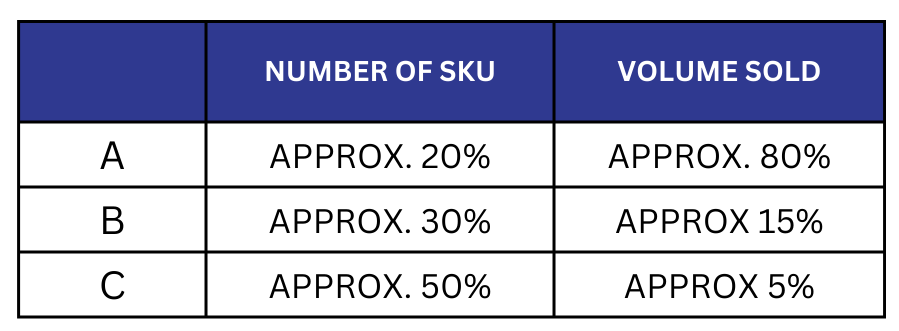

ABC inventory analysis is a methodological titan among inventory management techniques. By distinguishing stock items according to their importance, this analysis segments products into three broad categories—A, B and C—each representing different levels of importance and investment. As a general rule, “A” items are the most valuable, although they may represent a smaller fraction of all items, requiring more intense monitoring by management. “B” items are in the middle range, while “C” items make up the bulk of the stock, but are the least valuable.

This analysis allows us to categorize items according to their output volume and acquisition cost. In fact, it helps us to better understand

- the products you have in stock

- the time they spend in your warehouse

- the volume they represent in your overall business, and

- the financial impact they have on your cost of goods sold.

Benefits of ABC Inventory Analysis

The advantages of integrating ABC inventory analysis into your supply chain practices are multifaceted.

1. Cost Reduction

By precisely managing high-value goods, you can significantly reduce holding costs and optimize order frequencies.

2. Inventory Control

With a clear view of inventory categories, you’re better equipped to prevent stockouts and overstocking, reducing the risk of obsolescence.

3. Improvements through ABC analysis

The third effect of this analysis is to improve several aspects for the organization.

Improved Customer Service

Understanding which items are most crucial to your clients helps prioritize service and maintain high satisfaction levels.

Stock life cycle

By understanding the volume of products issued, ABC analysis enables changes in volumes to be identified quickly. As a result, stock indicators such as minimum, maximum and order quantity can be quickly adjusted to track progress through the life cycle. This will help to better manage the costs mentioned above.

Positioning Products in the Warehouse

In a warehouse where employees move around to place items in stock and to prepare orders, it is essential to reduce this waste. See articleXxx for more details. In addition, this analysis can be used to determine in which bins the product should be placed, which will also help with picking. For example, a product with a high-output rate will be more accessible if it is placed in such a way as to reduce the movements and transport required to get to it.

Stocking Cycle Time

As A items represent a greater volume of stock outgoing, they are likely to represent a greater volume of stock in. Positioning them in the warehouse will therefore reduce the time it takes to put them in stock, as well as the time it takes to prepare orders.

ABC analysis is not always complete

There are certain sectors of activity for which ABC is not sufficient. Take the mining industry, for example. In their inventories, mines hold items that are very expensive, but which are rarely removed from stock. These items are, in a way, safety stocks to avoid stoppages in operations, which can be extremely costly. These stocks are called “strategic.” These strategic items will not be accounted for and managed in the same way as ABCs, which is why it is simpler to give them a different classification.

Implementation Challenges

However, no journey towards improvement is without its hitches. Anticipate some resistance to this change management process. Data inaccuracies or the unavailability of historical consumption data can challenge category assignment. Moreover, the need to seamlessly incorporate the ABC system within your existing infrastructure requires a deliberate and meticulous approach. Engage your teams early, empathize with transitional hesitancy, and focus on thorough training and communication to foster a smooth transition.

Data is the basis for better decisions.

Once the ABC analysis has been carried out, it is now time to ask ourselves a few questions. In the table below, we propose three main questions and some ideas for action in response to the data analysis.

| What does the data tell you? | · Stock in the warehouse represents activities

· Stocks are not what customers order

|

| What improvements can you make?

|

· Location in the warehouse

· Matching of related products in the warehouse · Adjustment of stock, minimum and maximum levels.

|

| What changes need to be made to purchasing?

|

· Frequency of supplier orders

· Evaluation of supplier capacity for growing items · Notification to supplier of items losing volume

|

Conclusion: Embracing Strategic Inventory Management

In recapitulation, ABC inventory analysis isn’t merely a tactic—it’s a transformative approach that champions judicious resource management and customer responsiveness. As stewards of an ever-evolving supply chain landscape, adopting ABC analysis will arm you with a powerful tool to champion efficiency and economic prudence.

Stay confident in the face of challenges and collaborative in bringing your teams along. Your expertise and commitment to success are the bedrock upon which progress in inventory management rests. With this strategic move towards ABC analysis, you are setting the stage for a streamlined, cost-effective supply chain that responds dynamically to the demands of a competitive marketplace.

As you stand at the threshold of transformation, we invite you to take definitive action. Begin your journey with the ABC inventory analysis today—optimize your operations, reduce waste, and enhance customer satisfaction. Your decision to embrace this change is not just a step towards innovation, but a leap into a future of sustainable success.

Reach out to us to discuss how we can support your endeavours. Together, let’s elevate your inventory strategy to new heights of excellence.