Scope 3 Reduction: How Scope 3 Lean Can Drive Sustainable Value Chain Transformation

In today’s business landscape, Scope 3 reduction has become a strategic imperative for companies striving to meet ambitious sustainability targets. Scope 3 emissions — indirect emissions originating from a company’s value chain — often represent the largest portion of an organization’s carbon footprint.

This article explores practical steps to reduce Scope 3 emissions, the role of Scope 3 Lean and continuous improvement, the benefits of reducing Scope 3 emissions, and inspiring examples of companies leading the way.

What Are Scope 1, Scope 2, and Scope 3 Emissions?

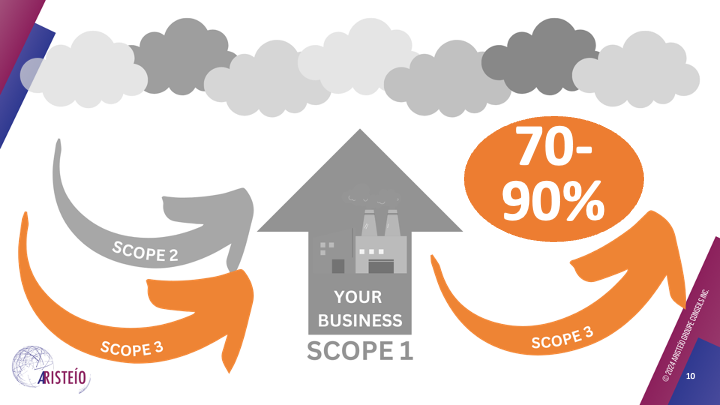

Before diving into strategies for Scope 3 reduction, it’s important to understand how greenhouse gas (GHG) emissions are categorized:

-

Scope 1 emissions are direct emissions from owned or controlled sources. These include emissions from company vehicles, on-site fuel combustion, and industrial equipment.

-

Scope 2 emissions are indirect emissions from the consumption of purchased electricity, heating, or cooling.

-

Scope 3 emissions are all other indirect emissions, including those from suppliers, business travel, product use, transportation, and waste disposal.

Scope 3 emissions are typically the most complex to measure and manage — but they also offer the greatest opportunity for impact.

5 Practical Steps for Scope 3 Reduction

To successfully reduce Scope 3 emissions, companies must collaborate across their value chains and implement systemic changes.

1. Engage Suppliers

Collaboration with suppliers is crucial to Scope 3 reduction. Provide tools, training, and support to help suppliers measure and manage their own emissions. Encourage adoption of renewable energy, low-carbon materials, and leaner production methods.

For example, companies can co-develop sustainability roadmaps with suppliers or create shared metrics and goals.

2. Adopt Circular Economy Principles

Circular economy practices — such as recycling, remanufacturing, and product life extension — help reduce emissions across the product lifecycle. Redesign products to use fewer materials, minimize waste, and improve recyclability.

A strong circular approach leads to long-term reductions in Scope 3 emissions while enhancing resource efficiency.

3. Improve Product Design

Eco-design is a critical lever for Scope 3 reduction. Focus on materials, energy consumption, durability, and ease of disassembly at end-of-life. This not only reduces environmental impact but also aligns with evolving customer expectations and regulatory requirements.

4. Optimize Transportation and Logistics

Transportation is a major contributor to Scope 3 emissions. Companies can lower their impact by using electric or hybrid vehicles, optimizing delivery routes, reducing packaging weight, and selecting low-emission logistics partners.

5. Encourage Sustainable Business Travel

Promote virtual collaboration, carpooling, and use of public transit. Consider internal policies that reduce unnecessary travel and support hybrid or remote work models. These actions can significantly reduce business-related travel emissions.

Using Continuous Improvement and Scope 3 Lean for Emissions Reduction

Scope 3 Lean refers to the application of Lean and continuous improvement (CI) tools to minimize environmental waste across a company’s value chain. These methodologies help identify inefficiencies and drive long-term improvements in emissions performance.

Here are some ways to apply CI tools to Scope 3 reduction:

1. Value Stream Mapping with a Green Lens

Map your processes to identify where emissions are generated. Add environmental data — such as energy use and waste — to visualize hotspots and uncover Scope 3 opportunities.

2. Use the DMAIC Framework

The DMAIC approach (Define, Measure, Analyze, Improve, Control) is ideal for managing sustainability projects. By defining Scope 3 emissions problems and applying root cause analysis, organizations can prioritize and sustain impactful changes.

3. Lean Tools for Sustainability

Tools like 5S, Just-in-Time (JIT), Kanban, and Total Productive Maintenance (TPM) can optimize operations, reduce overproduction, and eliminate energy waste. These Lean principles directly support the goals of Scope 3 Lean initiatives.

Benefits of Scope 3 Reduction

Reducing Scope 3 emissions delivers tangible business and environmental value:

-

Stronger Brand Reputation: Demonstrating environmental responsibility strengthens relationships with investors, customers, and partners.

-

Cost Reduction: Leaner operations, better logistics, and improved resource efficiency translate into real savings.

-

Regulatory Compliance: Proactive action ensures readiness for evolving environmental regulations and ESG reporting requirements.

-

Risk Mitigation: Reducing Scope 3 emissions improves supply chain resilience and lowers exposure to climate-related disruptions.

-

Innovation and Growth: Sustainability fosters innovation, creating new markets for eco-friendly products and services.

Real-World Examples of Scope 3 Reduction

Many global companies have successfully taken action to reduce Scope 3 emissions. Here are a few notable cases:

-

Mars Inc. partnered with major suppliers, reducing Scope 3 emissions by 6% since 2015, even as the company grew.

-

HP applied data-driven strategies to reduce emissions across product design, manufacturing, and transportation.

-

IKEA adopted a circular economy model, redesigning products and collaborating with suppliers to cut emissions.

-

Apple invested in recycled materials and green logistics, significantly reducing product-related emissions.

-

Unilever engaged its entire value chain to improve logistics, packaging, and sustainable sourcing practices.

Take Action: Your Path to Scope 3 Reduction Starts Now

Reducing Scope 3 emissions is no longer optional — it’s a critical step toward building a resilient, future-ready organization.

Start by assessing your Scope 3 emissions footprint. Engage with suppliers and value chain partners to identify opportunities. Apply Scope 3 Lean and continuous improvement methods to unlock efficiencies and drive measurable impact.

Every improvement counts. Whether it’s redesigning a product, optimizing delivery routes, or training your team in Lean principles, your actions can make a difference.

Ready to Take the Lead in Scope 3 Reduction?

Let’s work together to integrate sustainability into your operations and drive meaningful change. Our team specializes in helping companies apply continuous improvement and Lean methods to sustainability challenges.

Contact us today to start your Scope 3 Lean journey and reduce your environmental impact.

Sources:

The article was written from a conference we presented at the DEFY 2024 event in Montreéal, Canada.

Real-world examples: https://www.ceres.org/about

📸 Canva